Research Overview

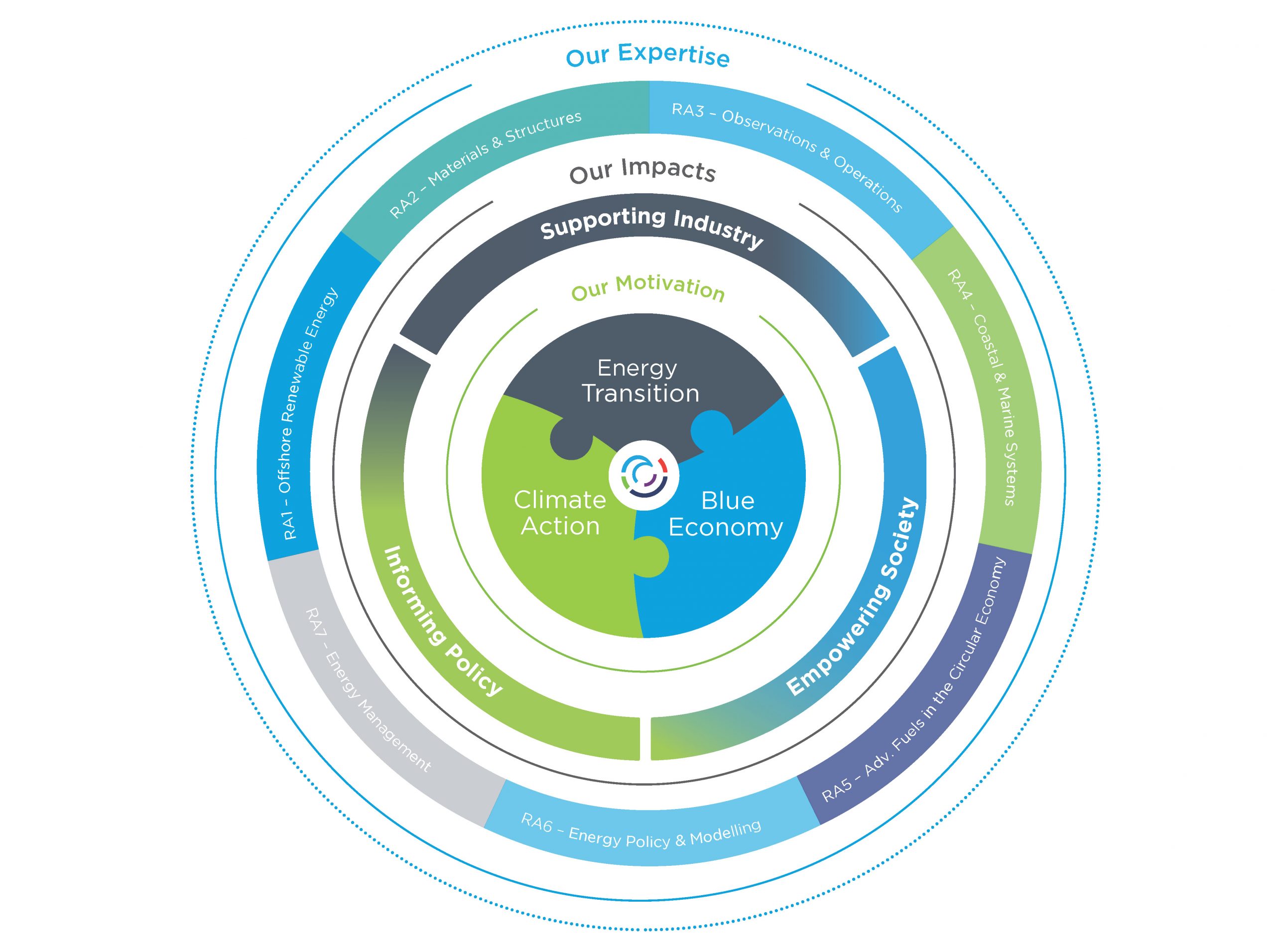

Central to the delivery of our research and impact priorities are over 200 world-class researchers who allow us to combine insights cross the areas of the Energy Transition, Climate Action, and the Blue Economy. Given their innate interdependency in terms of research focus and prioritisation, our belief is that none of these three areas can be considered holistically in isolation. Hence, while our research programme centres on these three research priorities, and associated impact-based priorities, it draws upon capacity from across seven underpinning areas of expertise, from which bespoke multi- and trans-disciplinary teams are built.

This provides a framework that enables us to seize upon opportunities arising from advances in energy, climate, and marine research and innovation to the benefit of all our stakeholders. It was developed through consultation with each of these groups, and as such represents a shared ambition for us to build upon our success to date to further develop as a world-leading Research Centre, and to contribute to Ireland’s economic development, environmental sustainability, and energy security

OUR RESEARCH PRIORITIES

In order to confront defined and urgent global challenges, our research programme seeks to address three research priorities, namely those of the Energy Transition, Climate Action, and the Blue Economy, which underpin and guide the forward development of our research activities. These research priorities are supported through challenge-based multi- and trans-disciplinary research activities that capitalise on our diverse skillsets, thereby promoting a truly collaborative research environment where optimised bespoke multi/trans-disciplinary teams are built for the purposes of addressing emerging challenges

OUR IMPACT PRIORITIES

Our research programme is furthermore underpinned by three impact-based priorities, namely those of Informing Policy, Supporting Industry, and Empowering Society, through which we seek to translate our research outputs into demonstrable and tangible impact, thereby ensuring that the benefits and return on investment are clear and quantifiable.

OUR UNDERLYING AREAS OF EXPERTISE

The delivery of our research and impact priorities draws upon capacity from across seven underpinning areas of expertise, from which bespoke multi- and trans-disciplinary teams are built. This provides a framework that enables us to seize upon opportunities arising from advances in energy, climate, and marine research and innovation to the benefit of all our stakeholders.